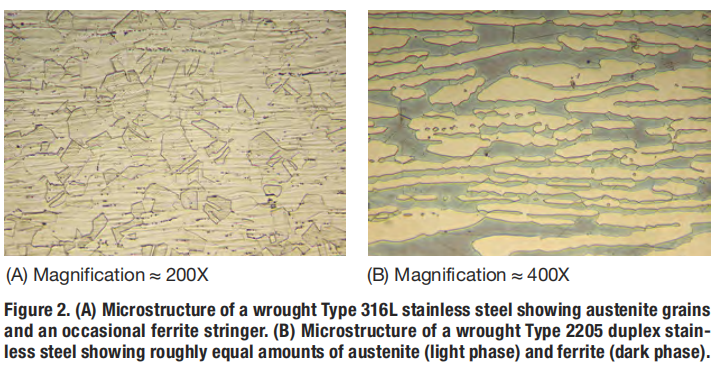

Type 316L stainless steel has a microstructure thatconsists of austenite phase and a very small volumeof ferrite phase. This is achieved primarily by addingsufficient nickel to the alloy to stabilize the austenitephase. The nickel content of wrought 316L stainlesssteels is typically in the range of 10-11%. Duplexstainless steels have a chemical composition that isadjusted to produce a microstructure that consists ofapproximately equal parts ferrite and austenitephases (Figure 2). With 2205 duplex stainless steelthis is accomplished by reducing the nickel contentto about 5% and adjusting the manganese and nitro-gen additions to yield approximately 40-50% ferriteThe chemical composition of the 2205 grade is bal-anced so that the austenite and ferrite phase haveabout equal corrosion resistance. The term “duplex”stainless steel refers to the dual austenite/ferritemicrostructure.

The increased nitrogen content and fine-grainedmicrostructure of 2205 duplex stainless steel resultin higher strength levels than those of commonaustenitic grades such as Types 304L and 316L stainless steel. ln the solution annealed condition the2205 grade has about double the yield strength ofType 316L. Depending on the design code used in theconstruction of the processing facility, this higherstrength can result in much higher allowable stressesfor the 2205 grade.In many applications this allowsthe reduction of the wall thickness resulting in reduced weight and cost savings

2205_Duplex_Pharmaceutical