Colorized stainless steel sheets are commonly produced through the process of PVD coating. In this process, a thin layer of metal or metal compound is deposited onto the surface of the stainless steel sheet using Physical Vapor Deposition (PVD) techniques. This deposited layer can be customized to achieve a variety of colors and finishes, providing decorative and aesthetic options for architectural, interior design, automotive, and other applications.

Here’s how the process generally works:

1. **Preparation**: The stainless steel sheet is cleaned and prepared to ensure a clean surface free from contaminants, oils, and residues that could interfere with the adhesion of the PVD coating.

2. **PVD coating**: The prepared stainless steel sheet is placed in a vacuum chamber, where the PVD coating process takes place. The chamber is evacuated to create a vacuum environment, and then a solid source material is vaporized using techniques such as arc evaporation, sputtering, or cathodic arc deposition. The vaporized material condenses onto the surface of the stainless steel sheet, forming a thin film.

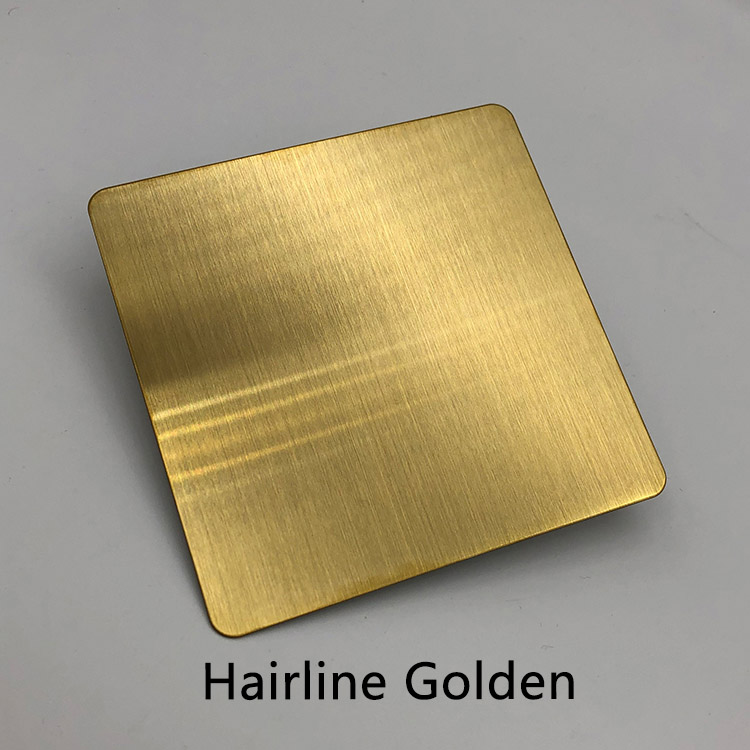

3. **Colorization**: The color of the PVD coating can be controlled by adjusting various factors such as the composition of the deposited material, the thickness of the coating, and the deposition conditions. Different metals and metal compounds can produce a wide range of colors, including gold, bronze, black, silver, blue, green, and red, among others.

4. **Finishing**: After the PVD coating process is complete, the colorized stainless steel sheet may undergo additional finishing steps such as polishing, buffing, or brushing to achieve the desired surface texture and appearance.

5. **Quality control**: The finished colorized stainless steel sheets are inspected to ensure that they meet the desired specifications for color, thickness, adhesion, and overall quality.

Colorized stainless steel sheets offer several advantages, including:

– Aesthetic appeal: The ability to customize the color and finish of stainless steel sheets allows for creative and visually striking designs.

– Durability: PVD coatings can enhance the durability and corrosion resistance of stainless steel, extending the lifespan of the material.

– Versatility: Colorized stainless steel sheets can be used in a wide range of applications, including architectural cladding, interior decoration, furniture, signage, and automotive trim.

Overall, PVD-coated colorized stainless steel sheets combine the aesthetic appeal of color with the functional properties of stainless steel, making them a popular choice for both decorative and functional applications.