| Type | Stainless steel sheet |

| Name | golden mirror stainless steel sheet 304 |

| Thickness | 0.3 mm – 3.0 mm |

| Size | 1000*2000, 1219*2438mm, 1219*3048mm,1500*3000mm,Customized |

| SS Grade | 304, 316, 201, 430 etc. |

| Finish | NO.4, Mirror, Hairline, Etching,Embossed,Vibration, Sandblast, Combination, |

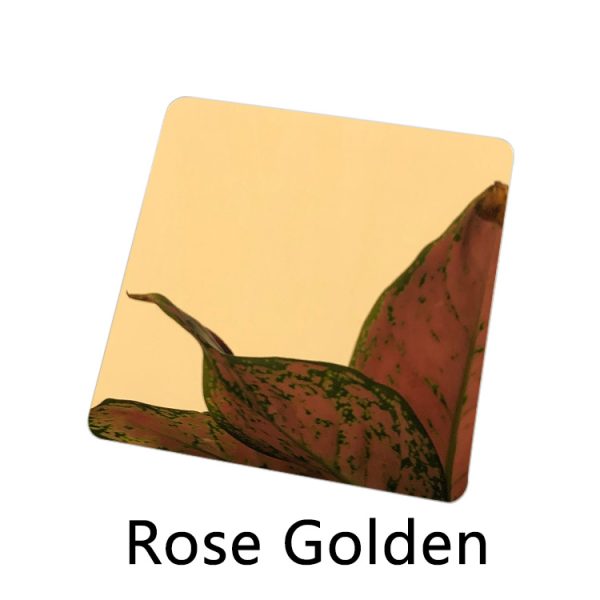

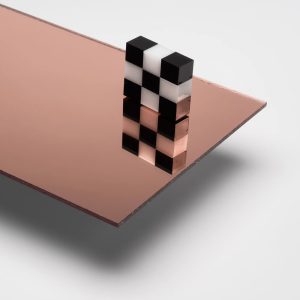

| Colors | Sliver, Golden, Rosed, Black, Bule, Green, Purple, Copper, Bronze |

| Origin | POSCO, JISCO, TISCO, LISCO, BAOSTEEL etc. |

| Packing | PVC+ waterproof paper +wooden package |

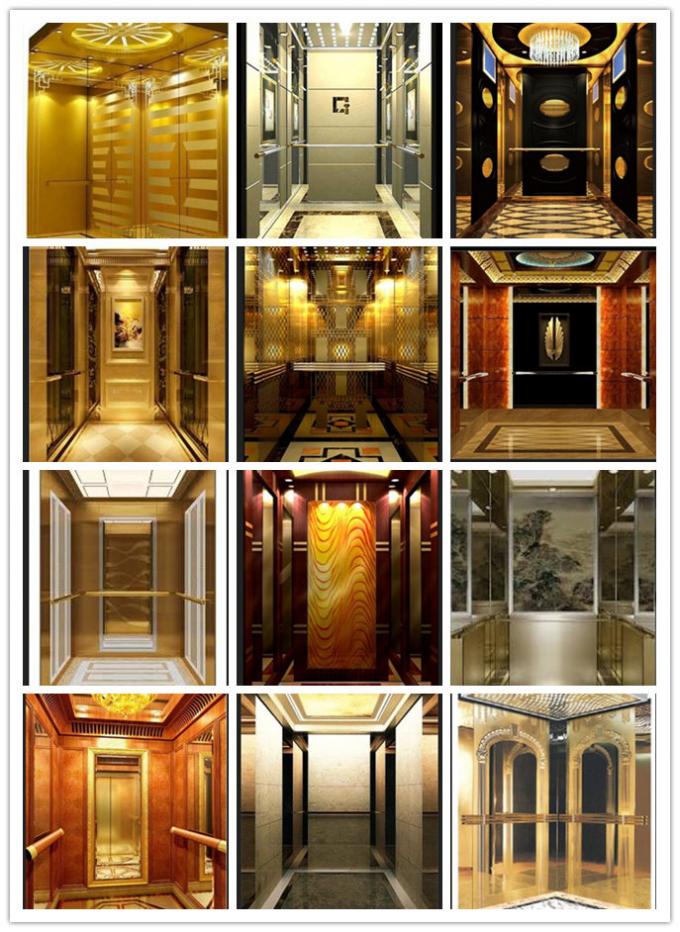

| Application | Construction, Indutry, Building, Chemical, Auto, Decorative |

| Chemical composition | ||||

| Grade | SUS 304 | SUS 316 | SUS 430 | SUS 201 |

| Elong(10%) | ≥ 40 | ≥40 | ≥ 22 | ≥35 |

| Hardness | ≤90HRB | ≤90HRB | ≤90HRB | ≤101HRB |

| Cr(%) | 18-20 | 16-18 | 16-18 | 16-18 |

| Ni(%) | 8-10 | 10-14 | ≤0.60 | 0.5-1.5 |

| C(%) | ≤0.08 | ≤0.07 | ≤0.12 | ≤0.08 |

As a professional PVD coating stainless steel supplier, we offer PVD-coated stainless steel for customers to choose from.Our PVD coating stainless steel, with physical Vapor Deposition (PVD), is a process to produce a metal vapor (titanium, chromium, and aluminum) that can be deposited on electrically conductive materials as a thin highly adhered pure metal or alloy coating. The process is carried out in a vacuum chamber vacum using a cathodic arc source.

The coating compounds are made up of various elements such as carbides, nitrides., borides, and silicide. A wide variety of colors can be achieved by adding different gases during the deposition.

This process can produce various colors, such as gray, gold, rose gold, champagne gold, antique copper, blue, green, purple, burgundy, and seven colors.

The production process of stainless steel color plate is as follows: first, stainless steel 2B plate is made with snowflake sand, wire drawing, mirror surface, sandblasting, etching, embossing and other processes on the surface. Next, the board is coated with PVD to create various colors. Finally, spray fingerprint free oil on the surface and apply PVC protective film.

This type of stainless steel color plate can remain unchanged indoors for 10 years and outdoors for 3-5 years. This product was subjected to continuous UV lamp irradiation for 400 hours in an authoritative laboratory for aging experiments, and the surface was not damaged. It has been proven that the product has very high reliability and is a mature and popular stainless steel surface treatment process.