| Type | Stainless steel sheet |

| Name | polished stainless steel sheet |

| Thickness | 0.3 mm – 3.0 mm |

| Size | 1000*2000, 1219*2438, 1219*3048, 1500*3000mm

Customize width=1000 1219 or 1500, length=1000~4000mm |

| SS Grade | 304, 316, 201, 430 etc. |

| Finish | 6K, Normal 8K, Super 8K, 10K Etc |

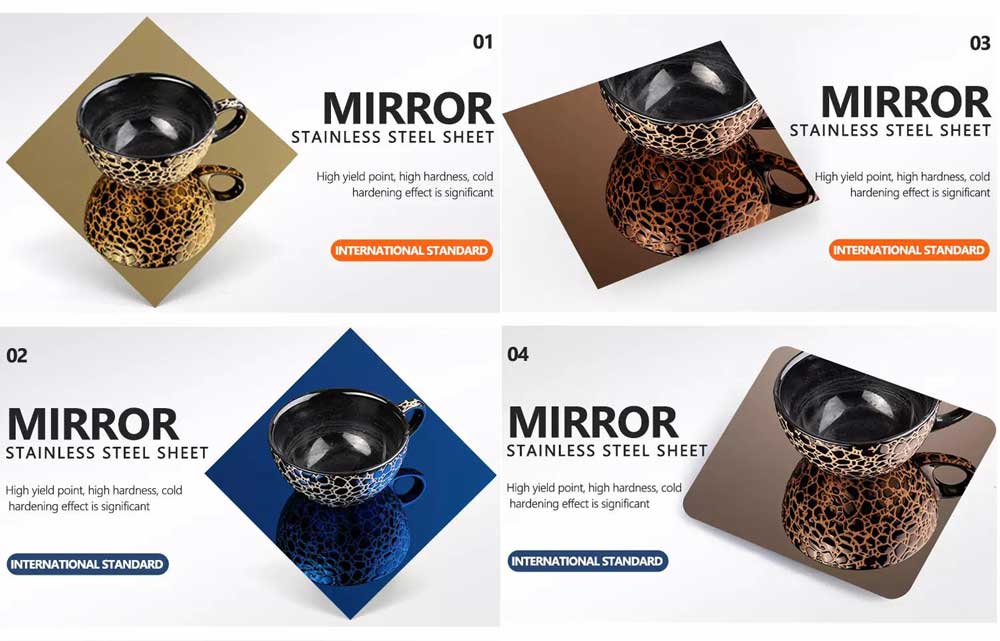

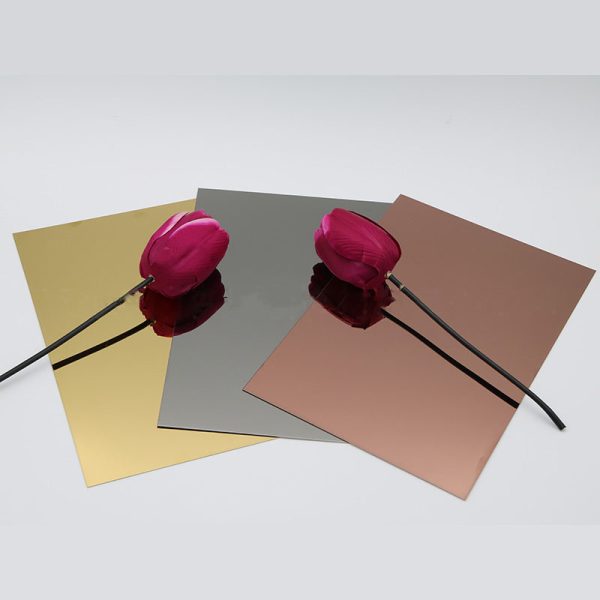

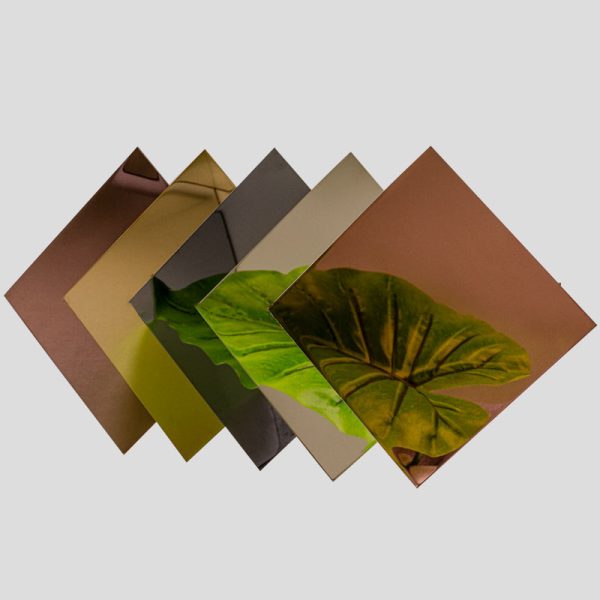

| Colors | Sliver golden black bule green purple copper bronze |

| Origin | Sliver, Golden, Rosed, Black, Bule, Green, Purple, Copper, Bronze |

| Packing way | PVC+ waterproof paper + strong sea-worthy wooden package |

| Application | Construction/Indutry/Building/Chemical/Auto |

Mirror stainless steel plate has a wide range of uses, in addition to being used as car foot plate, elevator panel, building materials, hardware, etc. It is also commonly used in home decoration. Mirror stainless steel can be used as the mirror wall of the storage room, which can expand the space, enhance the three-dimensional of the body, and also can be used as the TV wall. The patterned mirror is not steel, which is fashionable.

Stainless steel mirror panels have different levels of precision, including 6K, 8K, 10K, etc., and the larger the number, the higher the precision. 6K refers to the mirror panel with coarse grinding and polishing, 8K refers to the mirror effect, 10K refers to the mirror panel with fine grinding and polishing, and 12K refers to the mirror panel with ultra fine grinding and polishing.

Grade of stainless steel mirror panel:

1. Surface smoothness of stainless steel Lv.7 Ra 1.6 μ m. Rough surface with no mirror effect

2. Stainless steel surface smoothness Lv.8 Ra 0.8 μ m. Rough surface with no mirror effect

3. Surface smoothness of stainless steel Lv.9 Ra 0.4 μ m. 2B board, 4K surface

4. Stainless steel surface smoothness Lv.10 Ra 0.2~0.3 μ m. 6K surface with obvious mirror effect

5. Surface smoothness of stainless steel Lv.11 Ra 0.1-0.2 μ m. 8K surface, finely polished

6. Stainless steel surface smoothness Lv.12 Ra 0.02~0.16 μ m. 10K surface, finely polished

7. Surface smoothness of stainless steel Lv.13 Ra 0.015~0.02 μ M 12K surface, ultra precision polishing

The higher the grade of stainless steel, the better the stainless steel effect, and the brighter, smoother, and smoother the surface.

Production Process:

The production of stainless steel 8K sheets involves several stages, including:

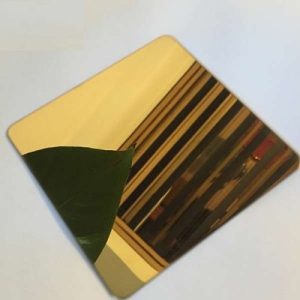

1. Initial Fabrication: The stainless steel is initially rolled into sheets and cut to the desired size.

2. Grinding: The sheets undergo multiple stages of grinding to remove any surface imperfections and achieve a uniform surface.

3. Polishing: The sheets are polished using finer abrasives and compounds to reach the 8K mirror finish. This involves multiple passes with progressively finer abrasives.

4. Finishing: The final polishing stage uses very fine polishing compounds to achieve the desired mirror-like reflectiveness.

5. Quality Control: The finished sheets are inspected for uniformity, reflectiveness, and any defects before being packaged for distribution.

Maintenance:

Maintaining the mirror finish of 8K stainless steel sheets requires regular cleaning with non-abrasive cleaners and soft cloths to avoid scratching the surface. For best results, it is recommended to use specialized stainless steel cleaning products that help preserve the reflective quality and prevent tarnishing.